Research Areas:

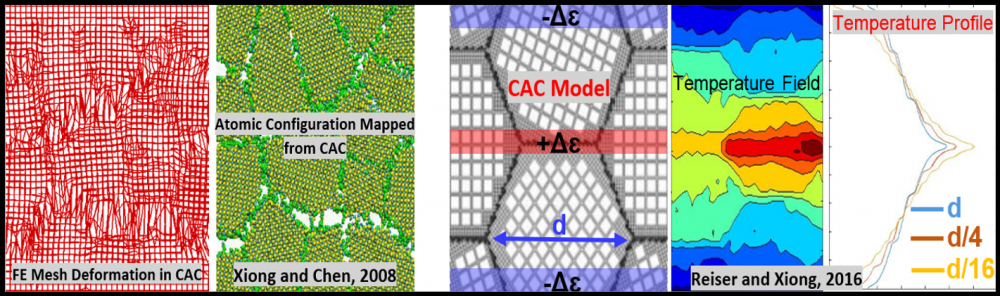

Link Atomistic to Continuum

[Read more...]

CG Simulation of Dislocations

[Read more...]

Multiscale Thermal Transport

[Read more...]

Dislocation-Interface Interactions

[Read more...]

Bio-inspired Composites

[Read more...]

Materials under Irradiations

Brittle-to-Ductile Fracture

[Read more...]

High-pressure Phase Transitions

[Read more...]

Nanostructured Ceramics

[Read more...]

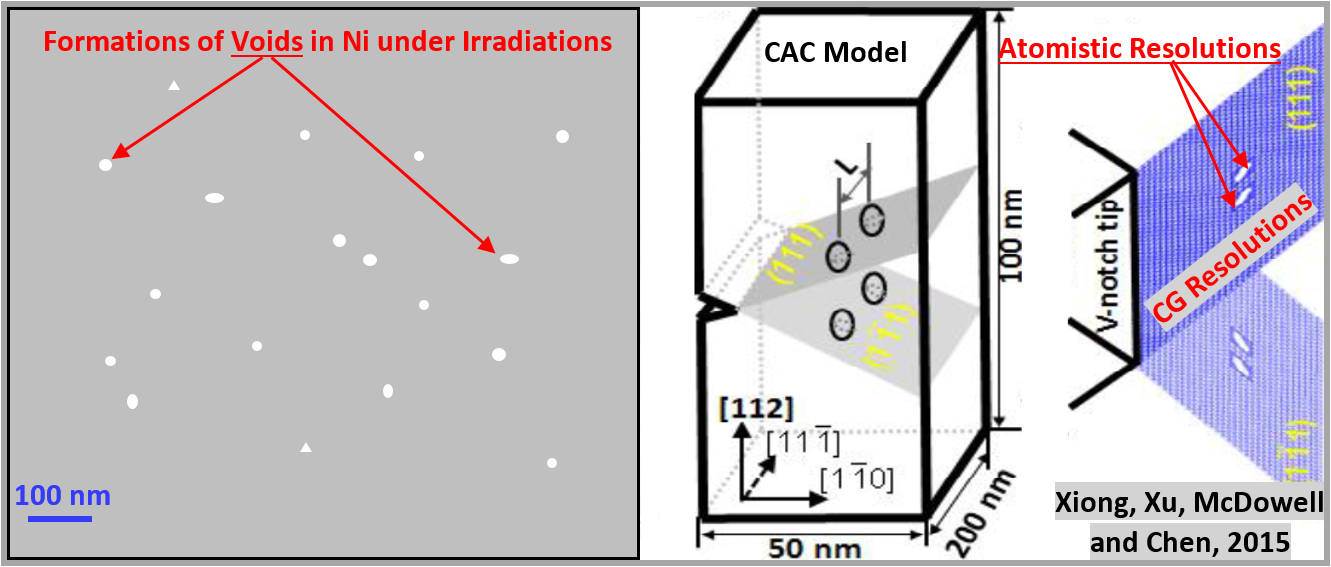

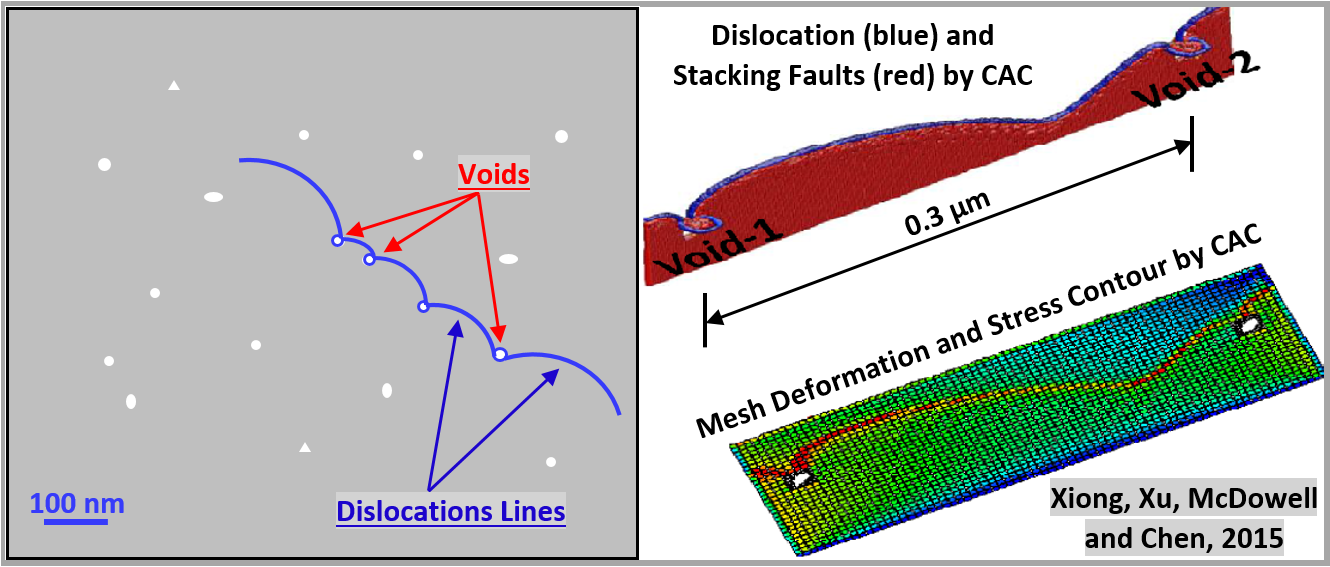

Materials subjected to irradiation exhibit elevated strength but suffer from reduced ductility by virtue of localized dislocation plasticity nearby irradiation-induced defects such as voids,stacking fault tetrahedra, and helium bubbles. Experimental studies indicate that such defects act as obstacles to dislocations, and, when by passed, lead to localization of deformation. To predict the in-service performance of materials in fusion energy facilities, we developed the concurrent atomistic-concurrent (CAC) method to render long dislocation lines on the order of microns, void spacings on the order of hundreds of nanometers, and also the atomic-scale short-range interactions between dislocations and obstacles in materials under irradiation.

Materials subjected to irradiation exhibit elevated strength but suffer from reduced ductility by virtue of localized dislocation plasticity nearby irradiation-induced defects such as voids,stacking fault tetrahedra, and helium bubbles. Experimental studies indicate that such defects act as obstacles to dislocations, and, when by passed, lead to localization of deformation. To predict the in-service performance of materials in fusion energy facilities, we developed the concurrent atomistic-concurrent (CAC) method to render long dislocation lines on the order of microns, void spacings on the order of hundreds of nanometers, and also the atomic-scale short-range interactions between dislocations and obstacles in materials under irradiation.

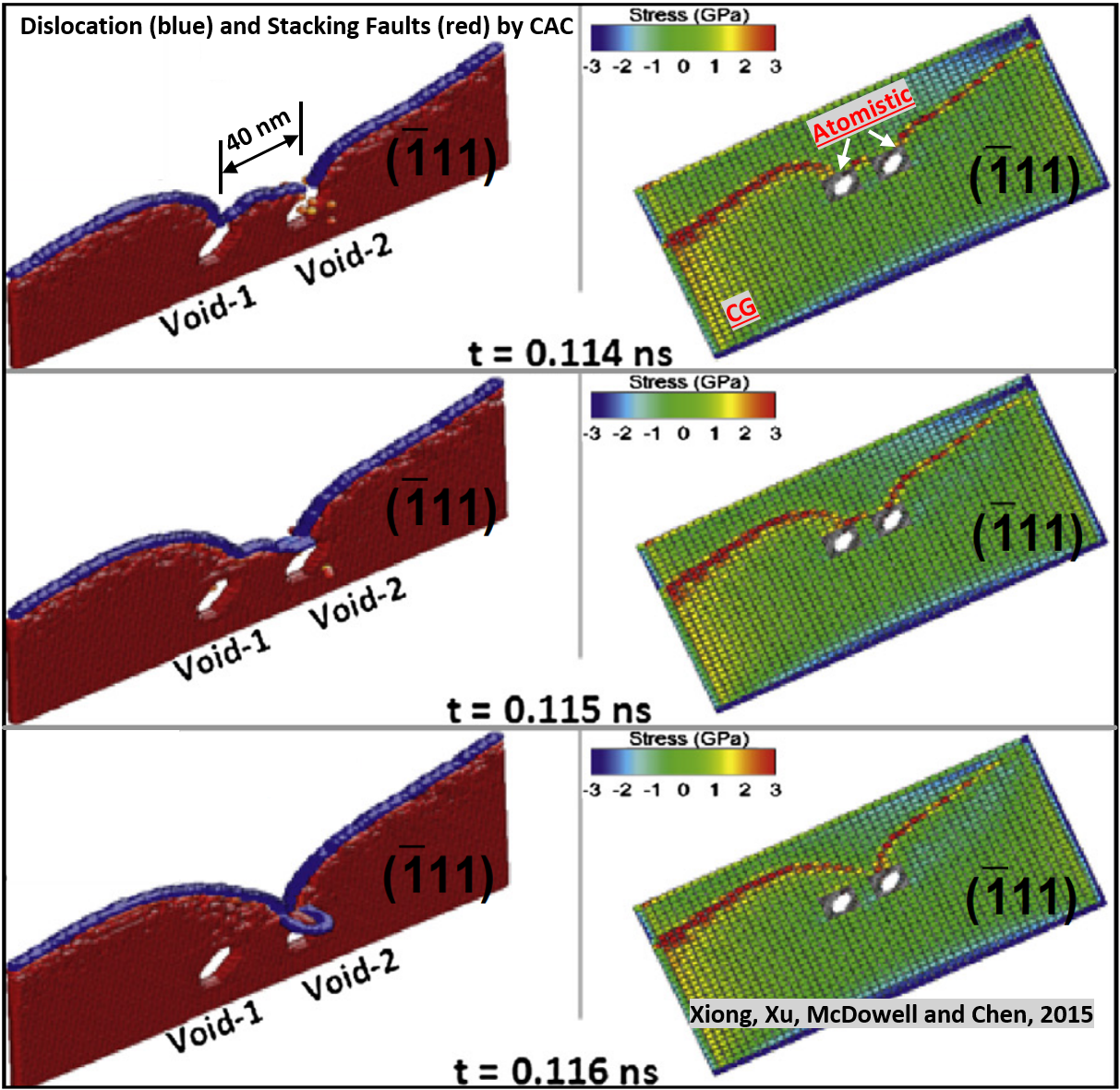

Fundamental to the CAC method is a unified formulation of atomistic and continuum representation of balance equations, which generalize Kirkwood's statistical mechanical theory of transport processes in materials. The following figures show a typical simulation result, i.e., the time sequence of dislocations, stacking faults, the local stress contour, and the FE mesh deformation, from CAC. Here a specimen containing ~20 million atoms was discretized into ~100,000 finite elements (FE). A fully atomistic resolution was retained around the periphery of two voids to investigate the details of atomic-scale dynamics during dislocation-obstacle interactions. Coarse FEs were employed away from the voids to significantly reduce the computational cost. A three-stage dislocation-obstacle interaction process was captured by CAC: (1) dislocation line encountered the obstacles; (2) dislocation line was pinned by the surfaces of obstacles; and (3) dislocation line broke away from the obstacles in materials under a critical shear stress.

References:

- Xu, S., Xiong, L., Chen, Y., and McDowell, D.L., 2016. An analysis of key chateristics of the Frank-Read source process in FCC metals, Journal of the Mechanics and Physics of Solids, in press, doi:10.1016/j.jmps.2016.08.002

- Xu, S., Xiong, L., Chen, Y., and McDowell, D.L., 2016. Edge dislocations bowing out from a row of collinear obstacles in Al, Scripta Materialia, 123, 135-139. doi:10.1016/j.scriptamat.2016.06.018

- Xiong, L., Xu, S., McDowell, D.L., and Chen, Y., 2015. Concurrent atomistic-continuum simulations of dislocation-void interactions in fcc crystals, International Journal of Plasticity, 65, 33-42. doi:10.1016/j.ijplas.2014.08.002