Research Areas:

Link Atomistic to Continuum

[Read more...]

CG Simulation of Dislocations

[Read more...]

Multiscale Thermal Transport

[Read more...]

Dislocation-Interface Interactions

[Read more...]

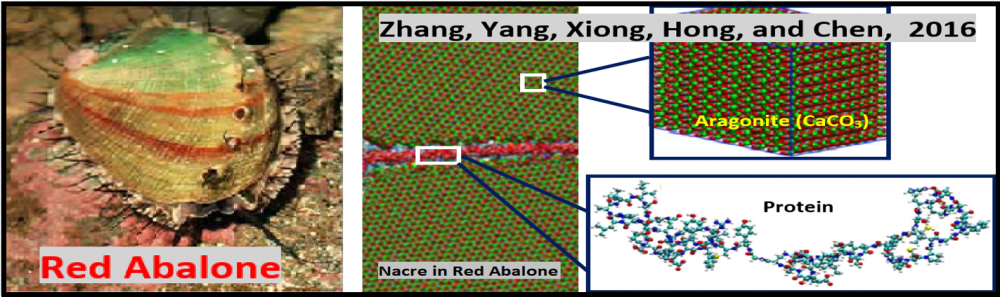

Bio-inspired Composites

[Read more...]

Materials under Irradiations

[Read more...]

Brittle-to-Ductile Fracture

High-pressure Phase Transitions

[Read more...]

Nanostructured Ceramics

[Read more...]

Over the past century, understanding of fracture has been significantly advanced due to many successful developments of experimental, theoretical, and computational methods. In particular, with the advent of high-performance computers, atomic-level molecular dynamics (MD) simulation has become a powerful tool to study material fracture at a very high resolution. Nevertheless, the current state-of-the-art MD simulations can handle several hundred billion atoms, amounting to a volume less than a cubic micron. It is unlikely, in the near future, for MD to fully resolve the complex fracture problems, such as arbitrary crack branching, crack-tip blunting, and brittle-to-ductile (BTD) transition, with realistic material size. To understand the failure of materials from the atomic to the macroscopic level, a coarse-grained (CG) atomistic model as well as an adaptive concurrent atomistic-continuum (CAC) method was developed to predict the dynamic brittle and ductile fracture in a variety of materials.

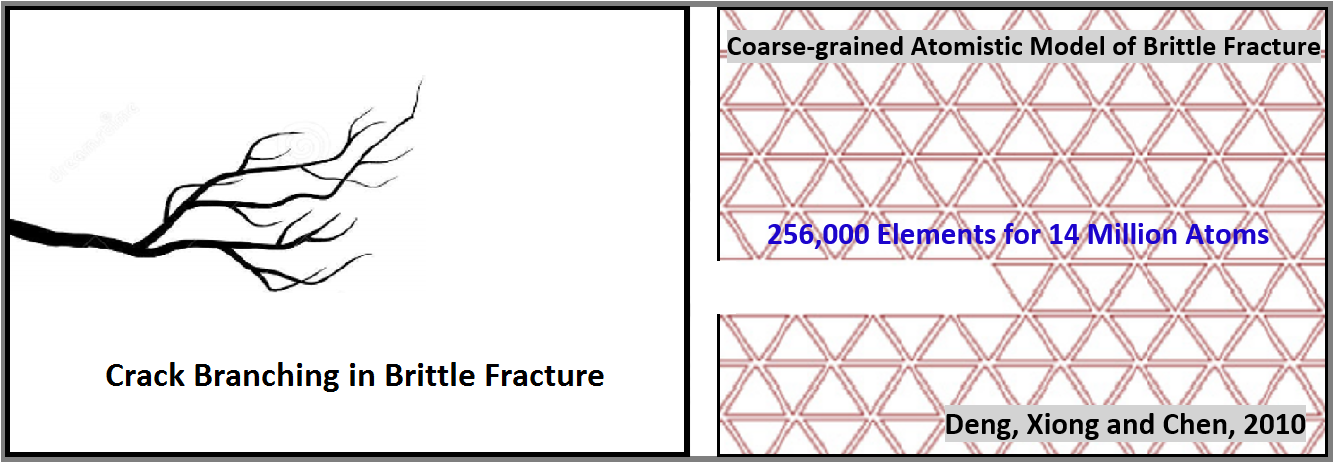

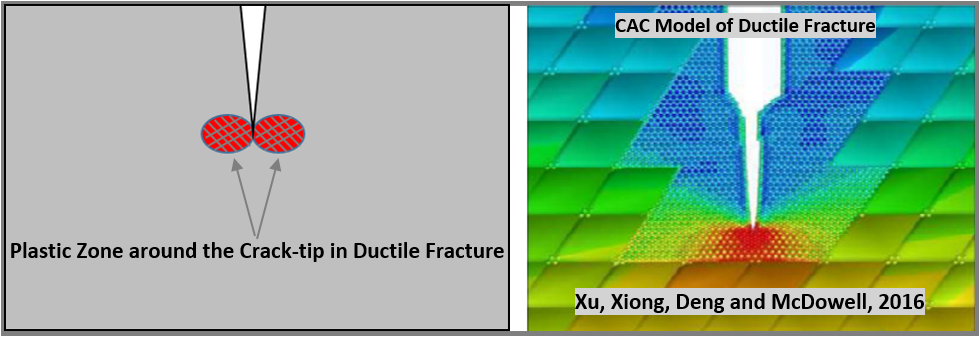

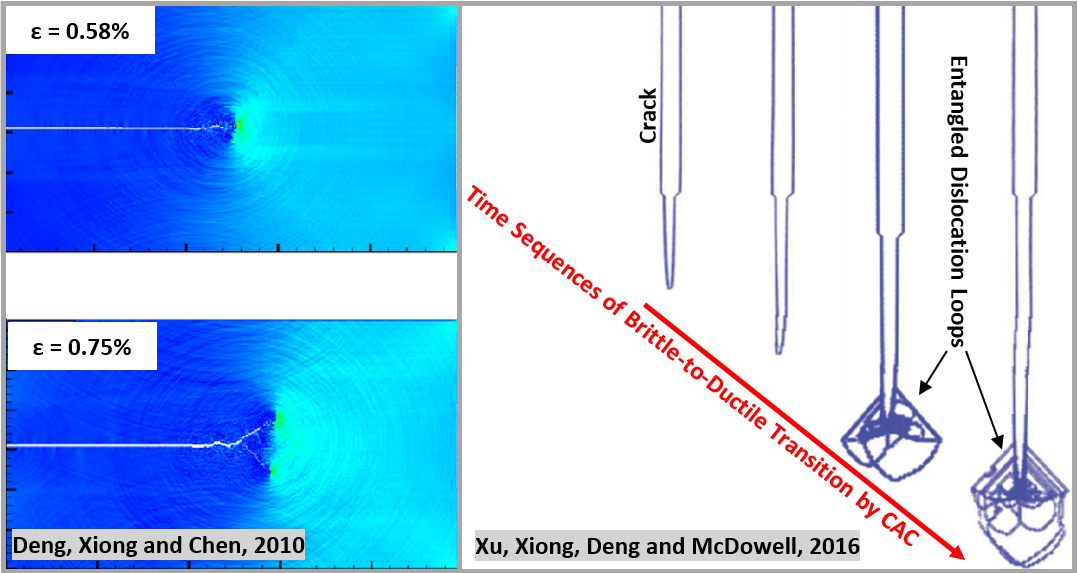

Over the past century, understanding of fracture has been significantly advanced due to many successful developments of experimental, theoretical, and computational methods. In particular, with the advent of high-performance computers, atomic-level molecular dynamics (MD) simulation has become a powerful tool to study material fracture at a very high resolution. Nevertheless, the current state-of-the-art MD simulations can handle several hundred billion atoms, amounting to a volume less than a cubic micron. It is unlikely, in the near future, for MD to fully resolve the complex fracture problems, such as arbitrary crack branching, crack-tip blunting, and brittle-to-ductile (BTD) transition, with realistic material size. To understand the failure of materials from the atomic to the macroscopic level, a coarse-grained (CG) atomistic model as well as an adaptive concurrent atomistic-continuum (CAC) method was developed to predict the dynamic brittle and ductile fracture in a variety of materials.

The following figures in the left column present the snapshots of dynamic crack propagation during the brittle fracture of a specimen by a CG model (~256,000 elements for ~14 million atoms). It was found that the interaction between the stress waves emitting from the propagating crack-tip and the stress waves reflected back from the sample boundaries significantly altered the speed, direction, pattern, and branching of the crack. The fundamental mechanism of brittle versus ductile response of stressed crack-tips is the competition between cleavage fracture by atomic decohesion and plastic deformation by dislocation nucleation and migration. Recently, the CAC method was furnished with a mesh refining scheme to simulate the BTD transition in ductile material fracture (figures as shown in the right column below). It was found that the BTD was not only sensitive to the strain-rate but also to the sample size. These preliminary results justified the applicability of our multiscale simulation tools in predicting brittle and ductile fracture of materials.

References:

- Xu, S., Xiong, L., Deng, Q., and McDowell, D.L., 2016. Mesh refinement schemes for the concurrent atomistic-continuum method, International Journal of Solids and Structures, 90, 144-152. doi:10.1016/j.ijsolstr.2016.03.030

- Deng, Q., Xiong, L., and Chen, Y., 2010. Coarse-graining atomistic dynamics of brittle fracture by finite element method, International Journal of Plasticity, 26,1402-1414. doi:10.1016/j.ijplas.2010.04.007